|

|

The ProCell series is an alternative development of the Glatt GF fluid bed series. Glatt Spouted Bed Technology also enables

particularly small, particularly large or irregular products to be Agglomerated/Granulated and Coated. The accurately

adjustable process air volume results in an outstanding energy balance.

Therefore the process is extremely economical.

Throughputs: 20kg/h to 2.5t/h.

|

|

|

|

Continuous multi-purpose

capability.

For the granulation and coating of products that are

difficult to fluidize.

Unique technology.

No sieve

bottoms.

Variable filter system.

Adjustment of flow profile by changing

the size of the gap.

Safety.

Explosion suppression

without pressure relief ducts.

Control system.

PLC or

PC-supported.

Insular solutions or network connection.

Integration into

higher-level systems.

|

|

|

Continuous multi-purpose capability

Glatt Spouted Bed Granulators of the ProCell series – in different designs

for all known processes in continuous operation:

Spray

Granulation

Agglomeartion

Coating (Film Coating; Lipid/Hot Melt

Coating)

Encapsulation of Liquids

Drying

Spray Drying

onto Inert Bodies

Due to the modular design, the air feed chamber, process chamber, filter

system and spray system can be combined in order to match the system to the

customer's specific process requirements.

Combination - the feed air chamber, which is divided into zones, allows

different process conditions to prevail in the process chamber. Typical

combinations are granulation with drying and/or cooling but granulation and

coating are also possible.

|

|

|

Unique technology

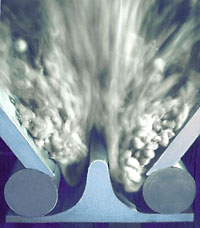

Unlike fluid bed processes, the air does not enter the process chamber

through a sieve bottom but through a longitudinal slot.

The speed of the process air when entering the process chamber can be

adjusted by varying the size of the gap. High speeds at this point ensure that

even large or irregular particles are fluidized.

|

|

|

|

|

|

|

View of the pilot system

of Glatt ProCell series |

View into the process chamber

|

|

|

Depending on the process requirements and the customer's request, Glatt can

provide internal filters in the form of filter bags or filter cartridges, filter

material according to the process requirements and an external filter or cyclone

in combination with a wet washer.

|

|

|

Safety

Explosion suppression systems allow a residual pressure shock resistance of

0.4bar to be realized. This can also be easily achieved

without using a round design.

|

|

|

Control system

SIEMENS, Allen Bradley, Mitsubishi and Freelance have already been

implemented, basically at the customer's request.

All control systems are designed and manufactured in-house by Glatt based on

hardware and software that has become established throughout the world.

The

advantage for you is an individual control system and world-wide local support.

This guarantees high availability for your system (-> Process Control Systems). |

|

|

|